Home / Maxi S-Compact 3.1

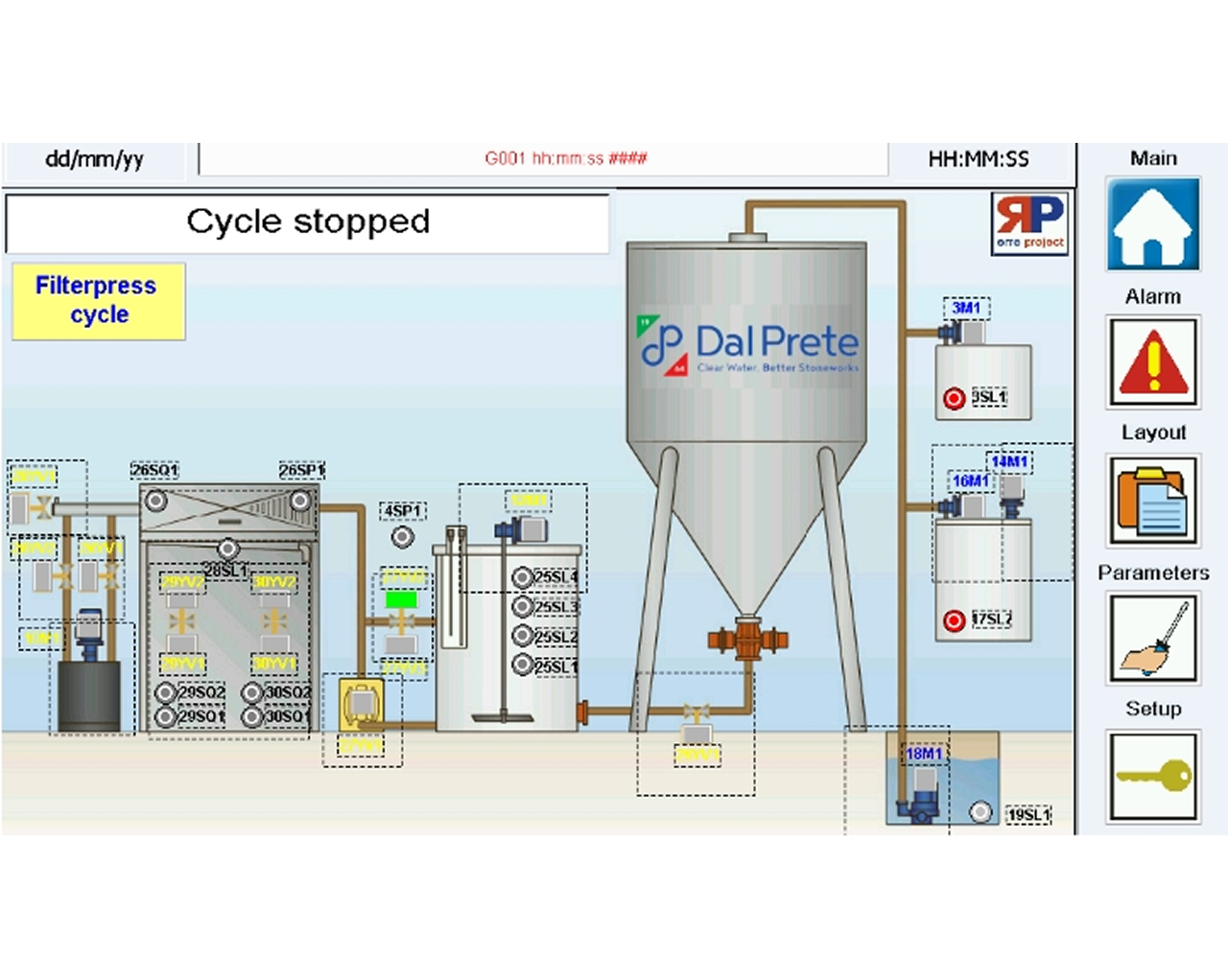

The Maxi S-Compact 3.1 is the Dal Prete plant designed to handle high volumes of water.

Designed for companies combining slab processing with block cutting, frequently working with large material thicknesses. Equipped with an extendable filter press and centralised controls, it offers high automation and consistent performance.

Clarified water production

Total installed power

Transport space

Filter press plates

Pressed sludge production

Hot-dip galvanized filter press with stainless steel cover and drainage channel.

Automatic chemical dosing station (flocculant and coagulant).

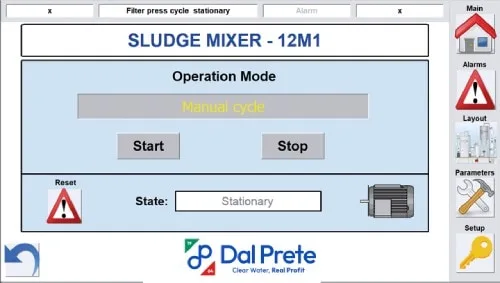

Control panel with 15,6” touchscreen to manage all plant operations.

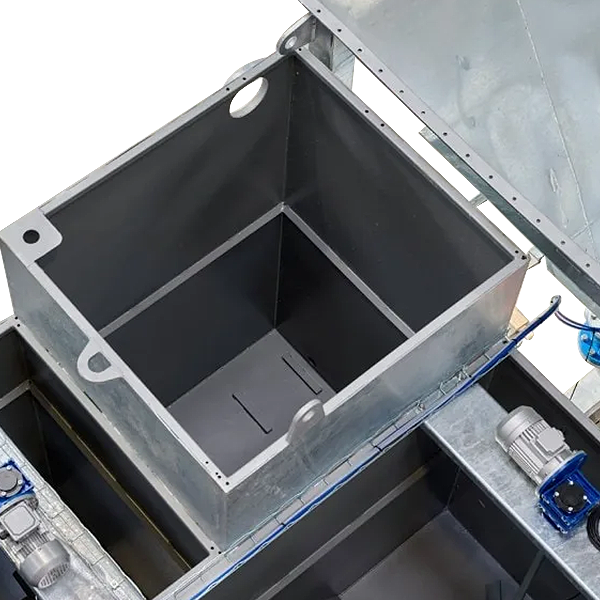

Sludge mixing tank.

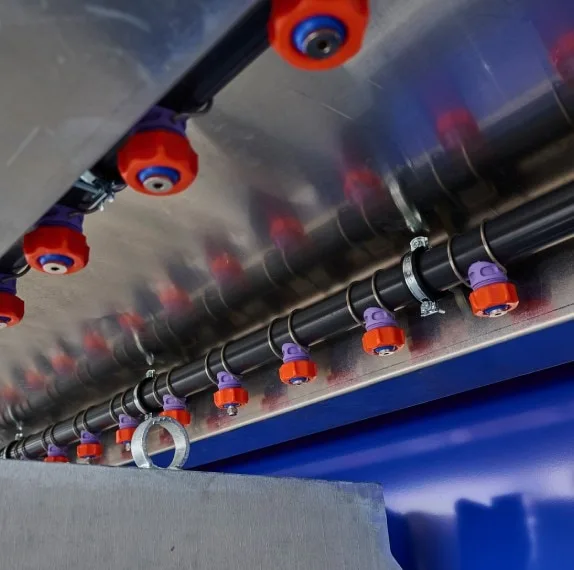

Detail of one of the automatic washes: nozzles spray clarified water to clean the filter press cloths.

Ultrasonic sensor for detecting sludge and flocculant tank levels.

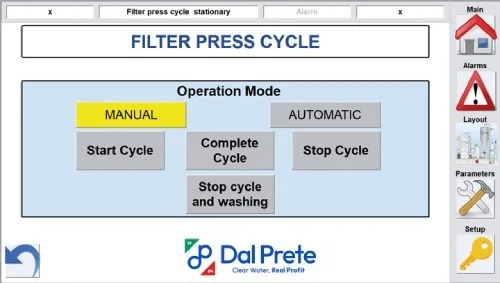

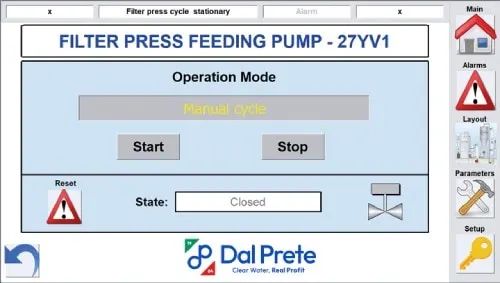

The DPURE 2.1 software was developed to minimise the need for specialised personnel on the system, through careful planning of its operation based on the company’s production schedule.

It allows for efficient and automated management of the washing times of components in contact with sludge, ensuring machine cleanliness and reliability.

The DPURE 2.1 software applied to the Maxi S-Compact 3.1 Premium has been developed to minimise specialised labor intervention through accurate scheduling of its operation based on the company’s production plan.

It efficiently and automatically manages cleaning cycles for components in contact with sludge, ensuring machine cleanliness and reliability.