Home / Mini Compact L 2.1

The Mini Compact L 2.1 is the most sold compact industrial water treatment system, as it meets the needs of most companies in the stone sector.

Designed for established workshops processing materials such as marble, granite, stone, ceramics, and composites, this system reduces operator involvement and provides the capacity to support future expansion.

Clarified water production

Total installed power

Transport space

Filter press plates

Pressed sludge production

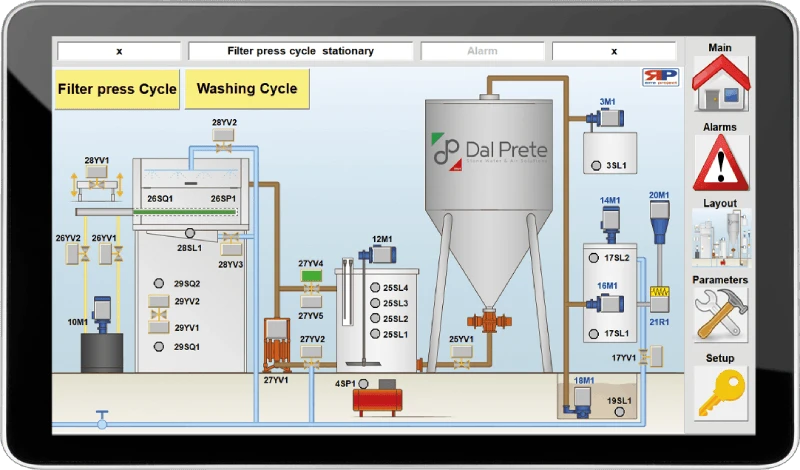

Control panel with 10” touchscreen to manage all plant operations.

Automatic flocculant dosing station.

Hot-dip galvanised filter press with stainless steel cover and drainage channel.

Water collection system from the filter press with automatic drip trays.

Overflow channel for clarified water at the top of the cylinder.

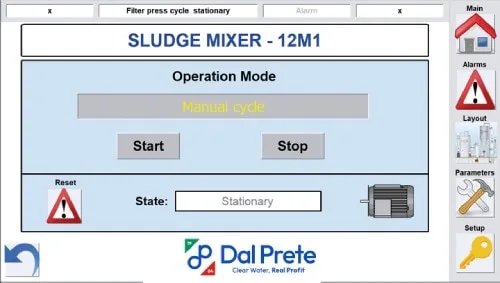

Hot-dip galvanised sludge homogenisation station.

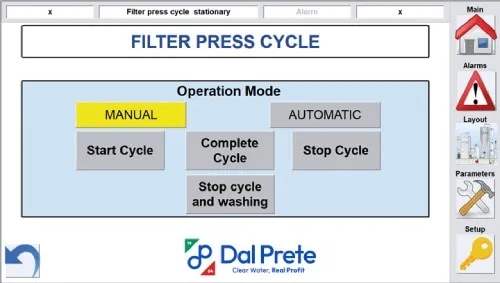

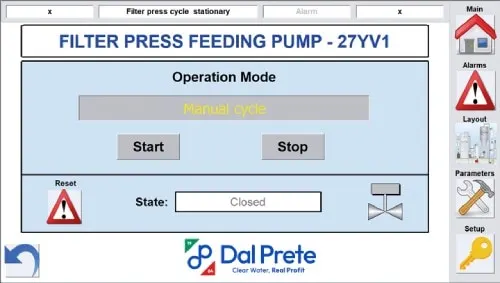

DPURE is Dal Prete’s proprietary software, developed and refined over time to meet the practical needs of its customers. It offers tailored solutions that streamline the scheduling and management of clarification and dehydration operations, making plant processes faster and more efficient.

With a focus on automation, DPURE ensures consistent and error-free performance across all stages of the treatment cycle. Its highly customisable functionality allows it to be adapted to each production site’s unique workflow and goals, enhancing both reliability and operational control.

The DPURE 2.1 software in the Mini Compact L 2.1 version is the ideal solution for workshops that handle large volumes of sludge and water.

DPURE facilitates the organisation of water treatment processes in structured production plants. In addition to managing the full process flow, it also controls the water collection system from the filter press, with automatic drip trays for easier disposal.